A good understanding of the mixing process and the physical phenomena that govern this process is a fundamental element to determinate the optimal design of an industrial agitator. However this understanding remains limited if it is not supported by a solid knowledge of the physical, chemical and also rheological properties of the different mixed products.

Our R & D unit has been created to assist you, in this complex framework, to determinate the optimal equipment and process to mix your products. We offer three levels of accompaniment:

Physical and rheological measurements:

- The dry matter content (DM %), called also total solids content (TS %).

- Bulk and apparent density (kg/m3).

- Viscosity and rheological behavior.

Mixing test

of your products, in our laboratory, using one of our tanks. This allows you to experimentally verify the efficiency of our technical proposal. We offer one or more tanks of different volumes: 3.5, 6, 20, 80, 400, 600, 1500L and 50 m3.

Whatever your process, we try to simulate it by applying the hydraulic conditions as close as possible to your industrial tank, ensuring the same efficiency on a large scale.

Depending on your process, you will be able to check:

- Sedimentations absence.

- Good visual mixing of several fluids and associated time.

- Solids dissolution and time required.

- Solids suspension.

- Powder dispersion.

- Chemical reaction.

Computational fluid dynamics / CFD

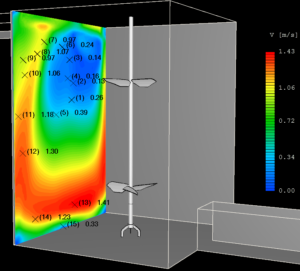

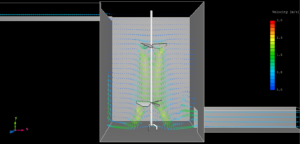

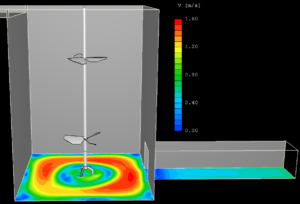

Below are some examples of numerical calculation results

Computational Fluid Dynamics / CFD of your process in industrial volume. Our CFD software is able to:

- Detect the velocity in all tank points and identify the dead zones. This is feasible in steady or transient state.

- Calculate the homogenization rate of two fluids as a function of mixing time.

- Estimate the exerted efforts on the propeller.

- Create videos illustrating the fluid moving in 2D or even in 3D.

- Calculate the return flow and display the associated surface.

- ...

With many other possibilities that can be made at your request. You can see below some examples of Computational Fluid Dynamics results.

Beyond these three support levels, our R & D unit can offer you more scientific, experimental and Computational Fluid Dynamics cooperation if you have a research project.

The art of mixing

The art of mixing